Torque Monitoring and Analysis for MINEBEA

Researchers and developers:

- Dr.Djitt Laowattana

- Dr.Pichit Rerkshanandra

- Kwanchai Muaydee

- Prakarnkiat Youngkong

Project owner:

- Minebea (Thailand) Co., Ltd.

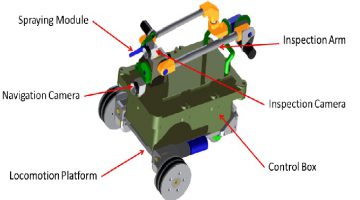

Figure 1 A bearing pivot is measured.

Minebea (Thailand) Co., Ltd. is a world-class manufacturing company who is providing high precision electronics and mechanical components for mainly computer markets. Recently, Minebea has been realizing that having data received from ball bearing inspection lines analyzed informs how well the ball bearing production process currently performs. Therefore, qualities of the product could be improved. However, investing in changing or modifying hardwares would be very costly. Applying such a software analysis seems to be a better solution.

According to the inspection process, measuring torque from ball bearings in real-time could be done by using a measuring instrument. The data, then, is transferred to a wave comparator and displayed on the LCD screen. After approximately 5 – 10 minutes, the screen would bring up a new data and delete the old one. Hence, the only data that could be recalled is what is left in the memory of the wave comparator.

Institute of Field RoBOtics [FIBO] at King Mongkut’s University of Technology Thonburi [KMUTT] and Minebea (Thailand) Co., Ltd. are collaborating towards a R&D development of monitoring and analyzing four torque quantities; max, min, average and peak-to-peak, received from the wave comparator. The result of applying statistical process analysis with the collected data would help Minebea see where in the production process the defection occurs.

The project is divided into two phases. Phase I consists of interfacing HIOKI 8731 wave comparator and managing data in real-time, and designing a network which would be able to handle 150 wave comparator while all data is collected at a central server. The project is currently up to the second phase where a statistical software is created.

Figure 2 Recommended network.

Beside beneficial information received directly from the torque analysis, the software could be used with other related products and processes. However, to receive an accurate result, adjusting database or raw data might be required.

Legacy of FIBO

Legacy of FIBO